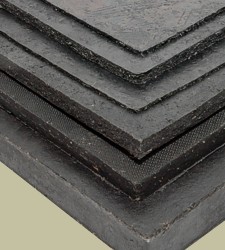

SymarŪ Load Bearing Pads

SymarŪ Load Bearing Pads are used extensively in standard construction applications, precast and prestressed concrete bridges, buildings and structural steel bearings applications, as well as machinery, equipment foundation, railway tie pads, and shock and vibration isolation.

Load Bearing Pads are made from Symar masticated rubber which is a fully cured fibre reinforced rubber made from a proprietary blend of recycled rubbers. During the manufacturing process synthetic fibres are added to the base rubber compounds to create an internal stiffening much like steel reinforced concrete. This mesh structure delivers enhanced tensile and compressive strength, stiffness, tear resistance, durability, and superior ozone and weather resistance. These properties cannot be matched by virgin product alone.

Symar XP

Our premium grade Symar XP Elastomeric Load Bearing Pads are constructed in a unique cross ply manufacturing process, giving uniform physical properties in all directions. These premium grade load bearing pads are designed for more demanding structural applications with greater load requirements.SymarŪ Load Bearing Pads are manufactured in continuous cure presses, not batch presses, which allows us to economically produce custom shapes and sizes and meet the demands of large scale construction projects. Load bearing pads can be supplied to specified dimensions ready for installation, including required cut outs and holes, or in sheet form for later sizing.

Ideal for:

- Bridge bearing masonry pads

- Lighting standard pad seats

- Handrail bearing pads

- Pads between steel beams, girders, and columns

- Pads between bridge and roof beams and substructures.

- Shock and vibration isolation

- Railway tie pad applications